Between its abundance of gut-healing amino acids, its benefits for joints and skin, its awesome flavor, and its ability to warm us up on a cold winter day, there are plenty of reasons to eat bone broth (and to make our own! See Why Broth is Awesome and Chicken Bone Broth). But, what about the downsides?

Table of Contents[Hide][Show]

There are plenty of myths circulating the internet about possible detrimental health effects of broth, most of which are demonstrably false. For example, we’ve already thoroughly busted myths about broth being harmful due to free glutamate levels and  heavy metal contamination (see Broth: Hidden Dangers in a Healing Food?). But there’s another possible concern when it comes to this nourishing food: oxidation. I first got thinking about this probability when my functional medicine doctor mentioned seeing a pattern of increasing LDL and triglycerides in clients consuming homemade broth on a regular basis. I think this may be attributable to, not to the broth itself, but that delicious layer of fat that rises to the top of our broth. It might be tempting to save for cooking (or even to slurp down with the broth itself), but could the prolonged exposure to heat and oxygen during the traditional 24-hour to 4-day simmering cause some of it to oxidize and become harmful?

heavy metal contamination (see Broth: Hidden Dangers in a Healing Food?). But there’s another possible concern when it comes to this nourishing food: oxidation. I first got thinking about this probability when my functional medicine doctor mentioned seeing a pattern of increasing LDL and triglycerides in clients consuming homemade broth on a regular basis. I think this may be attributable to, not to the broth itself, but that delicious layer of fat that rises to the top of our broth. It might be tempting to save for cooking (or even to slurp down with the broth itself), but could the prolonged exposure to heat and oxygen during the traditional 24-hour to 4-day simmering cause some of it to oxidize and become harmful?

Unfortunately, there aren’t any studies measuring how much oxidation occurs in the fat rendered from bone broth. However, we can apply what we know about oxidative rancidity, the composition of different animal fats, and the broth-making process to get a sense of what’s most likely going on!

Lipid Oxidation

Lipid Oxidation

Saturated, monounsaturated, and polyunsaturated fats are distinguished by the number of double bonds in their carbon chains (saturated fats have no double bonds, monounsaturated fats have one double bond, and polyunsaturated fats have multiple double bonds). Because these double bonds are essentially missing hydrogen atoms, they’re molecularly unstable, and can easily oxidize—undergoing a series of reactions leading to free radical production and rancidity in the presence of heat, light, and air.

The oxidation rate for a fatty acid increases with the number of double bonds it has. So, while saturated fats are relatively stable, monounsaturated fats are slightly more oxidation-prone, and polyunsaturated fats can be extremely oxidation-prone given the right conditions (such as during cooking!).

Oxidation Potential of Animal Fats

So, how does this apply to the ingredients in bone broth? Although animal fat is sometimes thrown under the umbrella of “saturated fat,” this is a massive oversimplification! All animal fats contain a mixture of saturated and unsaturated fatty acids, including some linoleic acid (the same type of polyunsaturated fat abundant in vegetable oils). The unsaturated fat content in animal is at risk of oxidation during prolonged, oxygen-exposed, or high-temperature cooking. For example:

So, how does this apply to the ingredients in bone broth? Although animal fat is sometimes thrown under the umbrella of “saturated fat,” this is a massive oversimplification! All animal fats contain a mixture of saturated and unsaturated fatty acids, including some linoleic acid (the same type of polyunsaturated fat abundant in vegetable oils). The unsaturated fat content in animal is at risk of oxidation during prolonged, oxygen-exposed, or high-temperature cooking. For example:

- Beef fat: 37% saturated, 61% unsaturated (2% linoleic acid)

- Chicken or turkey fat: 29% saturated, 65% unsaturated (20% linoleic acid)

- Lard: 40% saturated, 59% unsaturated (11% linoleic acid)

To make broth, we simmer bones at a temperature just below boiling (typically 94 degrees C, or 200 degrees F). Although this temperature won’t cause fats to oxidize as rapidly as high-temperature cooking methods like frying, damage still does occur—especially because broth spends such a long time simmering (the cooking process can last anywhere from several hours to 48 hours and beyond!). Studies show that highly unsaturated oils like corn oil, olive oil, and mixed seed oil (canola, sunflower, and safflower) begin showing signs of oxidation after only 40 minutes at 80 degrees C, with oxidation increasing during longer cooking times and higher temperatures. So, especially when using bones from animals with a higher polyunsaturated fat content (like chicken and other poultry), we would expect to see a similar process occur in long-cooked bone broth. This is particularly true because the fat rises to the top of the broth and can spend many hours, or even days, exposed to not only heat, but also air (hello, oxidation!).

Reducing the Risk

Prolonged cooking times for bone broth have become the norm in recent years because it maximized bone demineralization, thereby increasing the mineral content of the finished product. I personally, prefer to simmer my bone broth for 36 to 48 hours, until the bones can easily crumble in my hands (at that point, the bones are perfectly edible too, although they aren’t the tastiest of things). Fortunately, we don’t need to give up the benefits of a low-and-slow-cooked bone broth to minimize the risk from consuming oxidized fats.

So, how do we reduce our exposure to potentially oxidized fat from bone broth without forgoing this wonderful food entirely?

- Skim the fat off the top of the broth and discard it instead of eating it (this is the easiest route!). We can scoop off the oily layer while the broth is simmering, or remove it after refrigeration when the fat hardens and turns whitish or yellowish. (Keep in mind, animal fat can easily gunk up plumbing, so put the fat in a waste receptacle and not down the sink!)

- Use bones from animals with a higher saturated fat content (more heat-stable) and lower polyunsaturated fat content (think: beef and lamb bones rather than chicken, duck, or turkey bones).

- Use bones from animals raised in non-industrial-polluted areas that are free from heavy metal contaminants. (Along with being harmful to the human body when consumed in excess, certain heavy metals—especially copper and iron—act as oxidation promoters and can increase the oxidation rate of fragile fats.)

- Avoid eating any broth fat that tastes “off” (rancid fat has a distinctly unpleasant taste!).

- Make broth using a pressure cooker in order to limit the fat’s exposure to oxygen. Go Instant Pot!

- Choose high-quality pre-made bone broths that already have the fat skimmed, like Kettle & Fire.

With these tips in mind, we can reap the benefits of bone broth without ingesting harmful oxidized fats!

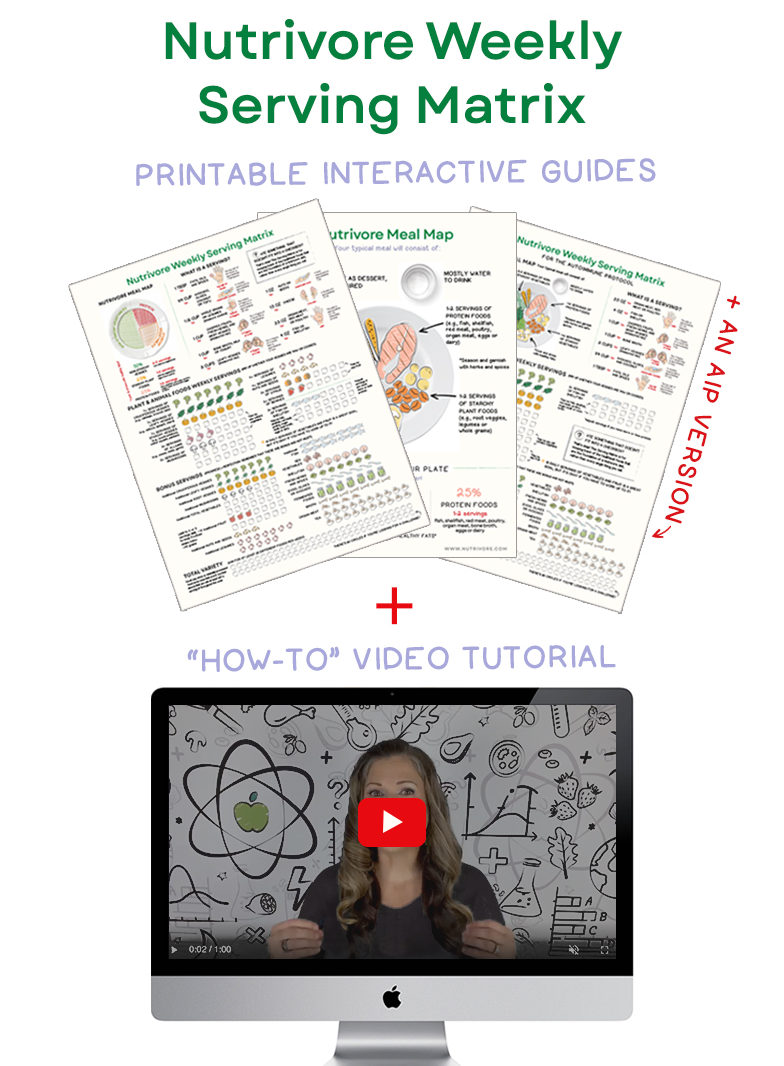

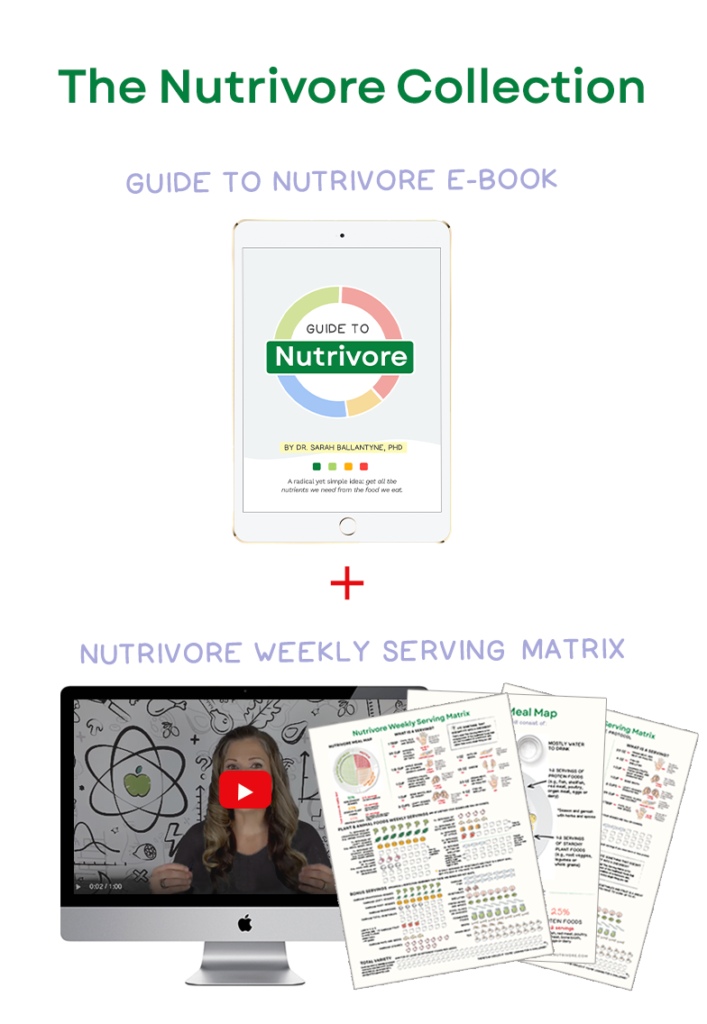

Nutrivore Weekly Serving Matrix

An easy-to-use and flexible weekly checklist

to help you maximize nutrient-density.

The Weekly Serving Matrix is very helpful! I’ve been eating along these lines but this really helps me know where to focus vs. which foods serve a more secondary role. It’s super helpful and has taken a lot of worry out of my meal planning. Thanks!

Jan

Citations

Cortinas L, et al. “Influence of the dietary polyunsaturation level on chicken meat quality: lipid oxidation.” Poult Sci. 2005 Jan;84(1):48-55.

Guillén-Sans R & Guzmán-Chozas M. “The thiobarbituric acid (TBA) reaction in foods: a review.” Crit Rev Food Sci Nutr. 1998 May;38(4):315-30.

Gunstone, F. Fatty Acid and Lipid Chemistry. Blackie: London, 1996.

Haywood RM, et al. “Detection of aldehydes and their conjugated hydroperoxydiene precursors in thermally-stressed culinary oils and fats: investigations using high resolution proton NMR spectroscopy.” Free Radic Res. 1995 May;22(5):441-82.

Moya MC, et al. “Analytical evaluation of polyunsaturated fatty acids degradation during thermal oxidation of edible oils by Fourier transform infrared spectroscopy.” Talanta. 1999 Sep 13;50(2):269-75.

Piette G, et al. “Influence of extraction temperature on amounts and quality of rendered chicken fat recovered from ground or homogenized skin.” Poult Sci. 2001 Apr;80(4):496-500.

Prabhu HR. “Lipid peroxidation in culinary oils subjected to thermal stress.” Indian J Clin Biochem. 2000 Aug;15(1):1-5. doi: 10.1007/BF02873539.

Zhang L, et al. “Effects of microwave rendering on the yield and characteristics of chicken fat from broiler abdominal fat tissue.” J Food Sci Technol. 2013 Dec; 50(6): 1151–1157.